In commercial printing Finishing is the process of applying additional processes after the completion of printing. Adding finishing can elevate your print materials with a sense of luxury, professionalism, and novelty to leave a lasting impression. One way to make a lasting impression is to make a literal impression in the paper with a finishing technique known as embossing and debossing.

How It Works

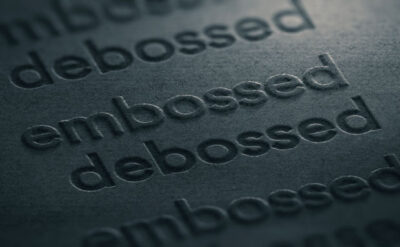

Embossing uses two metal plates that are transformed into a custom-made die and counter die with your design, pattern, logo, or text. Additionally, your printed materials undergo regulated pressure and heat, resulting in a raised relief on the surface. Similarly, debossing depresses the surface, creating a recessed design embedded in the paper. Moreover, the use of pressure and heat lends itself well to greater detail with crisp edges.

Embossing uses two metal plates that are transformed into a custom-made die and counter die with your design, pattern, logo, or text. Additionally, your printed materials undergo regulated pressure and heat, resulting in a raised relief on the surface. Similarly, debossing depresses the surface, creating a recessed design embedded in the paper. Moreover, the use of pressure and heat lends itself well to greater detail with crisp edges.

This design, stamped over ink or combined with hot foiling, creates a dramatic and truly unique effect. Or you can opt for a blind emboss or blind deboss. This means the design is stamped over an area with no ink or foil giving your print material a subtle and professional look.

Whichever you prefer, these finishing techniques add a sense of depth and texture to your design. Which is effective for creating memorable business cards, invitations, menus, presentation folders, and marketing materials for special occasions.

To begin with, Classic Impressions will help you understand what finishing processes are available to you. Additionally, we have the technical expertise to transform the print materials you have in mind into a finished product.

Reach out to us today to see how embossing and debossing will improve your print materials. Our team has over 30 years of experience in commercial printing to help you with your complex assembly print materials.